Electrolytic polishing and deburring

Main advantages of electrolytic polishing and deburring:

Cost savings as against manual treatment.

Improvement of quality – high brilliance through metallic clean surface. Gloss also in places where access is difficult, without deformation of sensitive parts, higher corrosion resistance of stainless steel parts (passivation).

New opportunities in the treatment of parts made from stainless steel, copper, brass and aluminium.

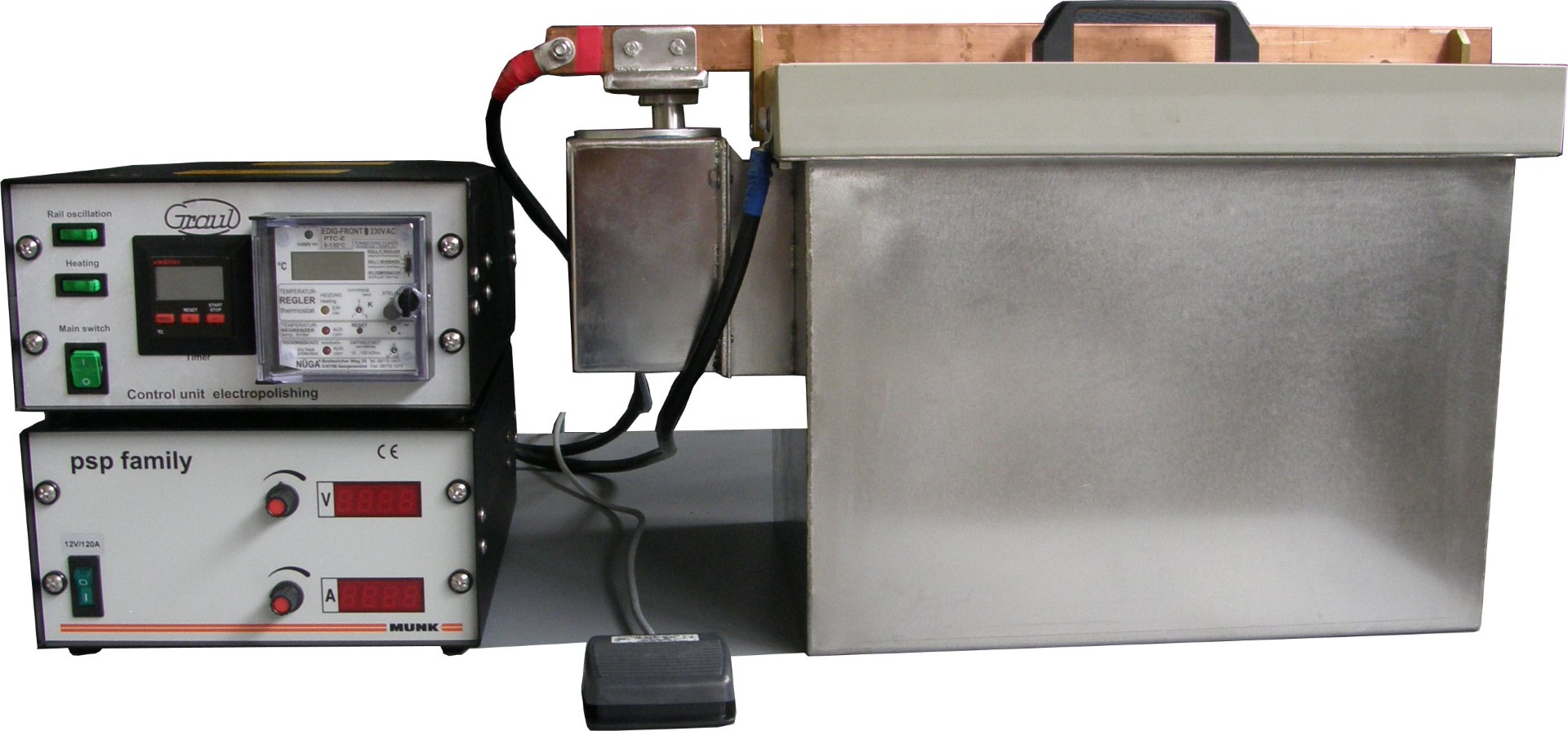

We manufacture equipment and supply electrolytes for your requirements, ranging from small 30-litre table equipment to medium and large-scale installations, for manual loading or automatic handling.

Our plant and electrolytes have been proven in practical operation for more than 40 years. We were among the first manufacturers of electropolishing equipment. Our experience and know-how can be demonstrated at any time.

Electrolytic polishing and deburring is often an interesting opportunity when mechanical treatment is too expensive or not possible at all. Let us advise you on the numerous and diverse applications.